How do you measure a field like electrical or magnetic fields? The field itself is of course not visible. But you can see the effects of a field and use that for the visualization. For example, in case of magnetic fields a nice high school type of experiment is to use iron filings sprayed around a magnet. The filings align along the field lines (so that the force on them is minimum), and this alignment makes the field lines visible.

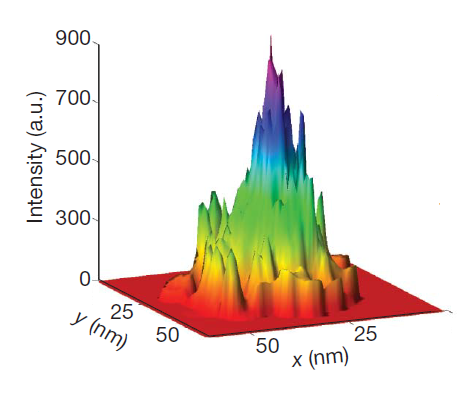

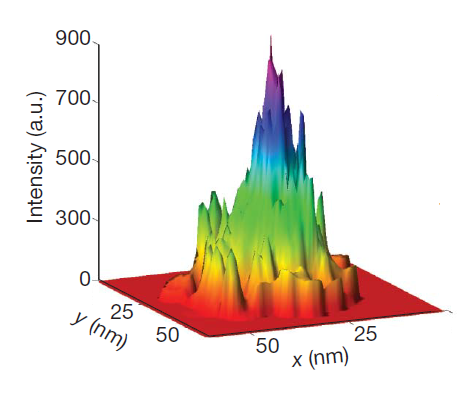

The electromagnetic fields of a hot spot on the surface of aluminium. The hotspot is only a few nanometres in size. (c) Nature Publishing Group. Nature 469, 385-389 (2011).

Although this kind of visualization technique works very well for larger objects, things get trickier if the fields are concentrated within the tiniest spots only a few nanometers large. There aren’t many objects that could be used to measure fields on that scale. Yet Xiang Zhang and colleagues from the University of Berkeley have achieved exactly that and developed a method capable of measuring the electromagnetic fields down to an area only 15 nanometres in size.

The fields they measure are so-called hotspots that form at the surface of metals or around metallic nanostructures such as nanoparticles or nanoscale bow tie structures. There, collective movements of the electrons – the surface plasmons – can create huge electromagnetic fields. This is very much in analogy to the way any other antenna works: oscillating electrical currents create electromagnetic radio waves. On the surface of metal nanostructures, the same happens; but because the geometry is so small the effect is much larger.

[…]

Continue reading...

I used to laugh at those TV series and movies where crime investigators could take a surveillance camera photo, however fuzzy and blurred, and enhance its resolution beyond belief to the point where every possible (and impossible) detail becomes visible. I stopped laughing last week at a conference when I became aware of a 2009 study by Moti Segev and colleagues from Technion in Israel that demonstrates an amazing precision in the recovery of objects from imperfect images. The resolution they achieve is better than what even the best photographic lens can ever hope to image.

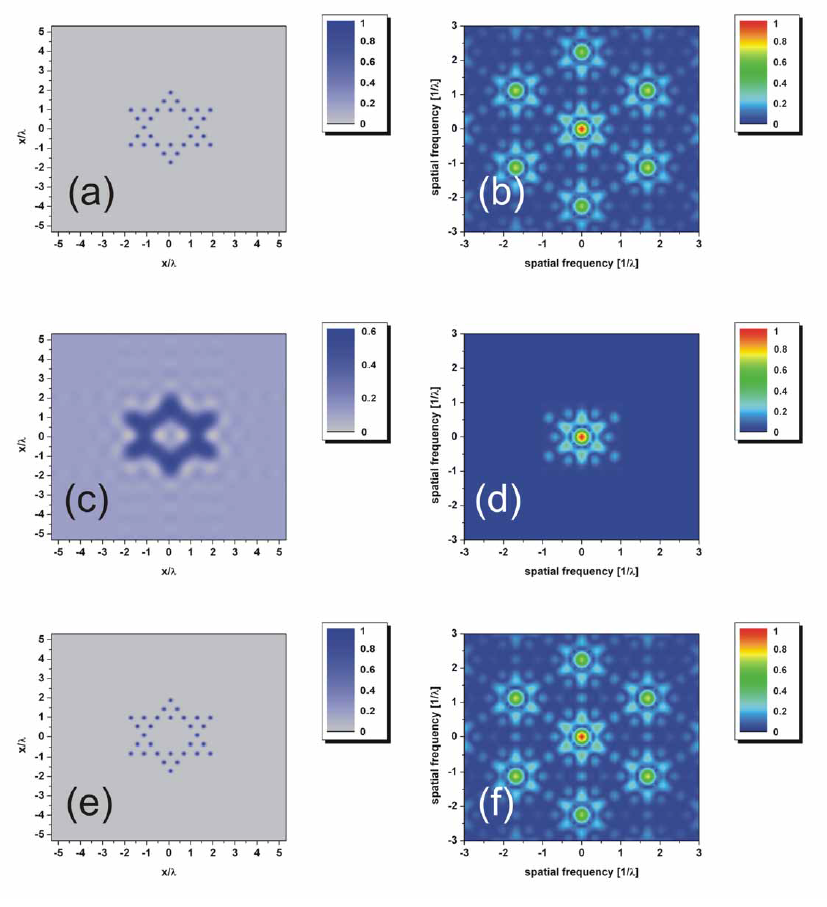

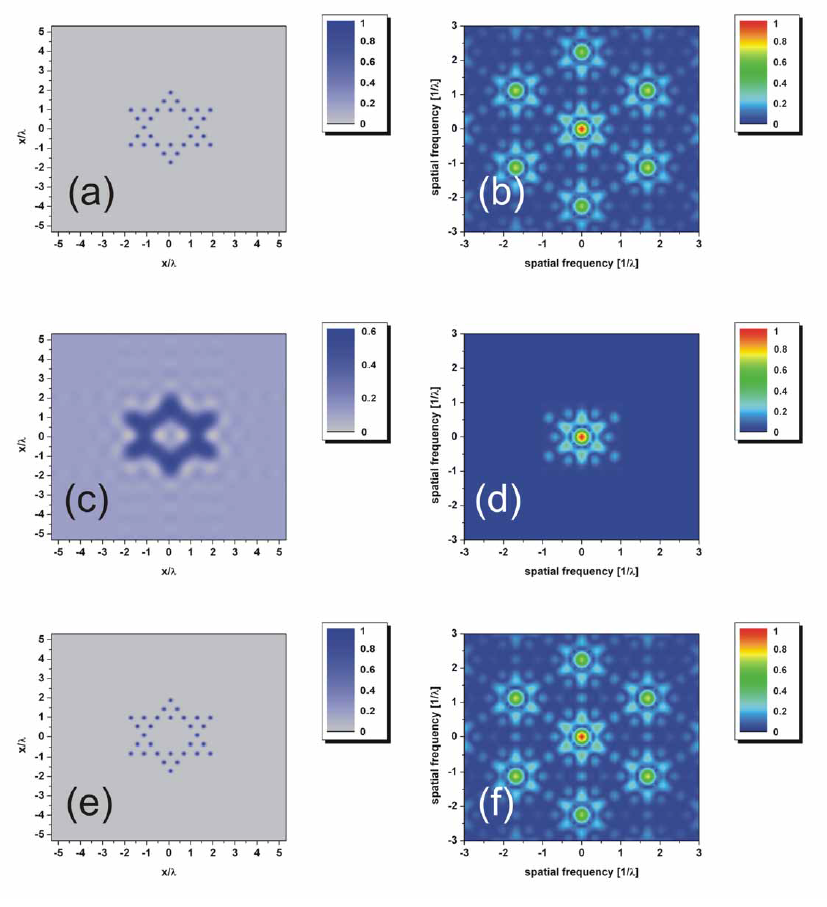

Enhancing image resolution. The top row shows the original object, both the image and its corresponding map showing the different frequencies that make up the image. Middle: the image as it would look like with the best resolution available with optical systems. Bottom: the reconstructed image. (c) Optics Express 17, 23920 (2009)

The notion of such an enhancement seemed so unbelievable at first because there is a maximum in resolution that a classical optical imaging system can deliver. This limit is about half of the wavelength of the light beams used. Any features smaller than this limit simply will not resolve however good the camera lens. Yet Segev and colleagues are easily able to beat this limit – without using any special equipment.

The reason for this limitation is that some of the light – the part that carries the information about the smallest features of an object – is absorbed by the medium through which light travels. Eventually, key information is missing from the image, and no exact mathematical reconstruction is possible.

How do you then reconstruct an image with high resolution? One option is to reconstruct the original object by making assumptions about the information that is missing. For example, if you know that a blurry image consists of the letters of the alphabet it becomes easier to guess the original. But such solutions are always restricted to certain circumstances and are also quite susceptible to noise in images.

[…]

Continue reading...

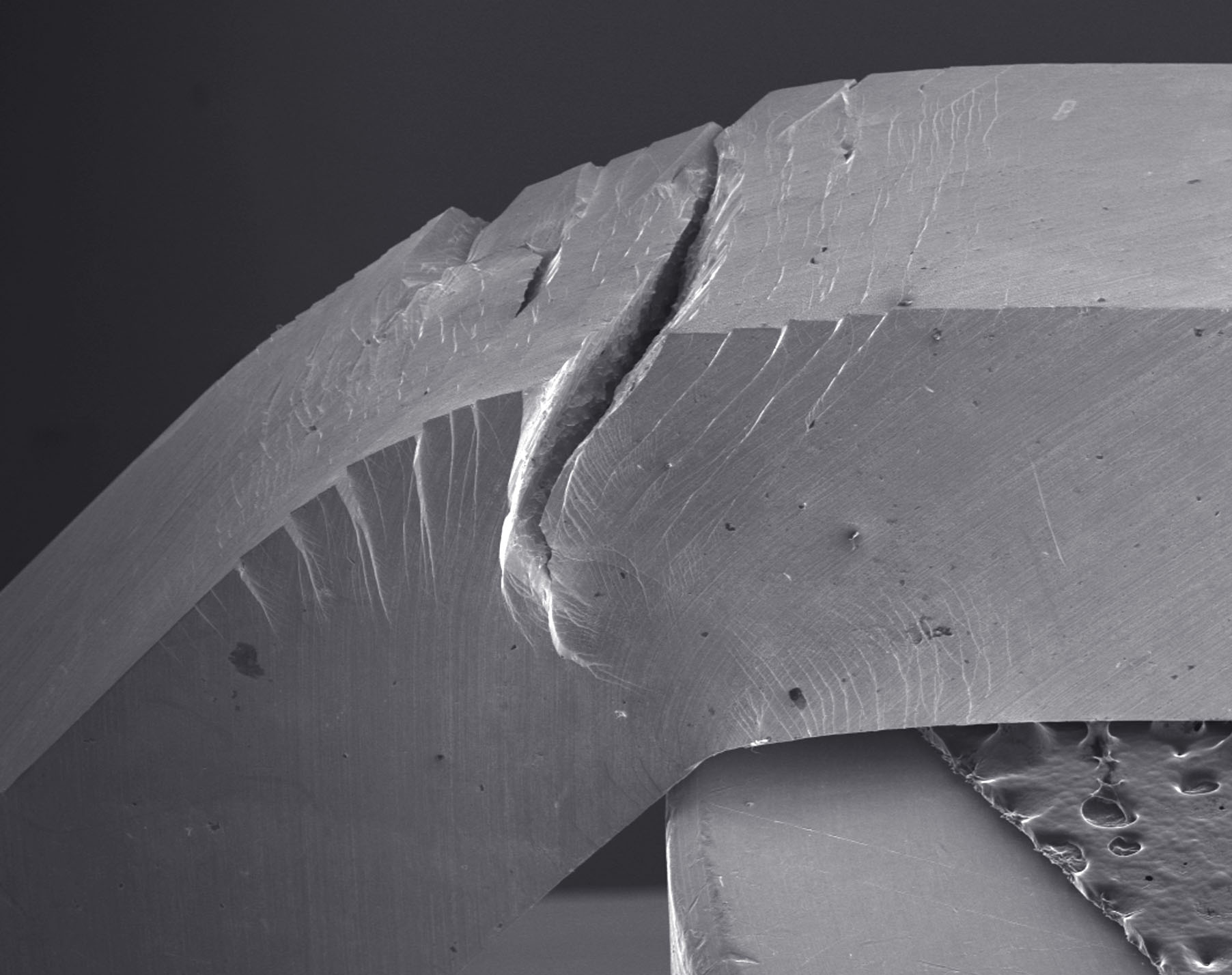

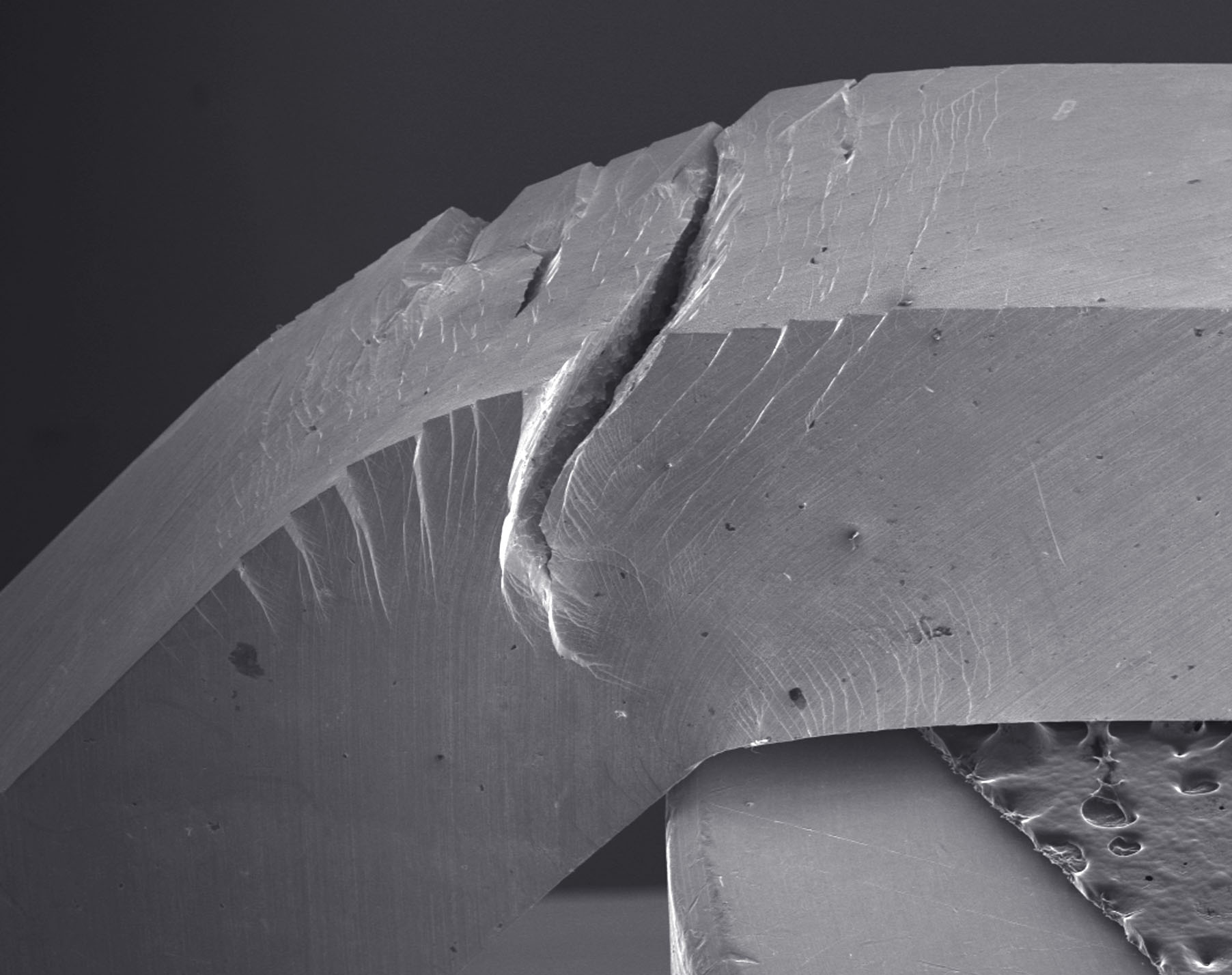

A tough metallic glass. This Pd79Ag3.5P6Si9.5Ge2 glass did not fracture catastrophically even after undergoing significant bending. Credit: Maximilien E. Launey

Glasses are very useful structural materials, because they are strong. You can stand on a glass table without it breaking. But once you put too much stress on a glass it breaks. Steels on the other hand are much tougher — which means that they show a much stronger resistance to fracture: rather than suddenly breaking under stress, steels tend to deform first. This toughness of steel is one of the obvious reasons why steel skeletons instead of glasses are used for the construction of large buildings.

This conception of glasses not being very tough is now made history by Marios Demetriou and colleagues from the California Institute of Technology and The University of California, Berkeley. They have discovered a glass that is not only strong, but also tough as steel. It is a metallic glass, which means that it dominantly consists of metal atoms. Like other metallic glasses it isn’t transparent, but looks like a normal metal — except that unlike crystalline metals its atomic structure is more or less random. The damage tolerance of this metallic glass, its combination of strength and toughness, is higher than any known material. “It has been usual to regard metallic glasses as damage sensitive, but over recent years it has become increasingly recognised that they can be tough. This new paper marks a further decisive shift in showing that metallic glasses can be very tough indeed,” says Lindsay Greer from Cambridge University, who studies the properties of metallic glasses.

[…]

Continue reading...

January 20, 2011

1 Comment